Pressure vessels are use to contain fluids, vapors or gases for the purposes of storage, mixing or transportation. Read More…

If you are looking for innovative pressure vessels, you’ve come to the right place! We actively manage your project every step of the way. We keep you informed of what we are doing to ensure we keep up to your standards and delivery times.

Gladwin Tank Manufacturing builds custom ASME pressure vessels. We work with stainless, carbon, duplex and the nickel alloys and offer custom rolling, plasma, and water jet cutting. Paired with our expertise in multiple welding procedures, we’re capable of handling every project, large and small. Contact us for your custom build requirements. We are more than just pressure vessels, we...

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

Midwest Tank Company has provided quality tanks to small and large corporations and contractors since 1972. Our reputation is built on exceptional services and customer satisfaction! Our fabrication techniques have been developed through years of tank specialization, combined with personnel who are experienced in all phases of our operation.

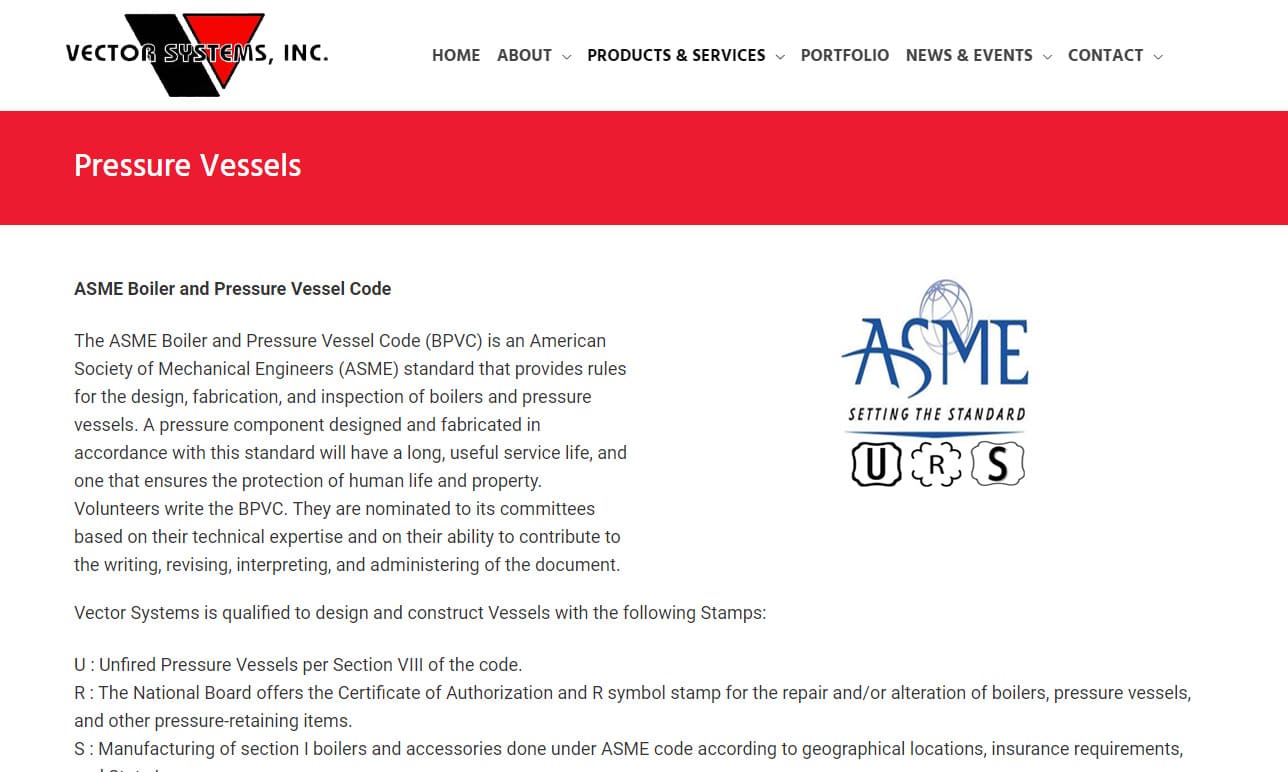

At Vector Systems, Inc., we are proud to specialize in the design, fabrication, and maintenance of pressure vessels, catering to the diverse needs of our valued clients. With our extensive expertise, unwavering commitment to quality, and dedication to customer satisfaction, we have established ourselves as a trusted leader in the industry. Our primary focus is on providing top-quality pressure...

More ASME Tank Manufacturers

The ASME code of vessel manufacturing standards is the most commonly followed one, although specialized industries may have their own further requirements for manufacturing standards. ASME tanks are used in a wide range of industrial applications such as chemical, pharmaceutical, food and beverage, oil and fuel and plastic industries.

Engineers are required to abide by ASME standards for design components such as materials used for vessel construction, size, shape, temperature range and intended pressure level. In addition, once being used for processing applications, tanks and vessels are required to be regularly inspected and maintained according to ASME levels, checking for leaks, cracks or ruptured seams.

As every process which uses a pressure tank is under great force and compression, even small irregularities or cracks in a vessel could result in both property and physical damage due to an explosion, fire and flying shrapnel metal. ASME pressure vessels are measured in gallons according to their capacity, and can range anyway from 50 to several thousand gallons.

Many specifics of ASME tank construction are dependent on the intended application of the tank. There are standard options which are able to meet a wide variety of pressure vessels needs, however tanks can also be constructed according to custom specifications.

There are a number of other construction options when it comes to designing tanks such as: removable or attached lids, stands and supports for tanks that are situated on their sides, stairways and ladders for individuals that work around large tanks, sight glass windows for monitoring the liquid inside, and process plumbing for applications requiring the process.

There are three common processes that engineers usually create ASME vessels with: forging, welding and brazing, all of which involve heating pieces of metal and then joining them in the form of the vessel. Furthermore, tanks can be horizontally or vertically placed, with support braces for larger tanks to prevent collapse if necessary.

They can be located above ground or underground, depending on their intended use and whether easy access to a tank is a factor in the process or not. Smaller tanks can be mounted on the back of a large truck or vehicle and used for portable storage, mixing or processing. Tanks can be made of stainless steel, titanium, carbon steel, nickel or aluminum, or from thermoplastics with high strength properties.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services