Pressure tanks are containers that hold gases, vapors, and fluids at high pressures. They are used in many industrial applications for chemical, pharmaceutical, food and beverage, recreational and oil and fuel processes, and they are also often found in conjunction with well systems that supply water to residential homes or buildings. Read More…

If you are looking for innovative pressure vessels, you’ve come to the right place! We actively manage your project every step of the way. We keep you informed of what we are doing to ensure we keep up to your standards and delivery times.

Gladwin Tank Manufacturing builds custom ASME pressure vessels. We work with stainless, carbon, duplex and the nickel alloys and offer custom rolling, plasma, and water jet cutting. Paired with our expertise in multiple welding procedures, we’re capable of handling every project, large and small. Contact us for your custom build requirements. We are more than just pressure vessels, we...

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

Midwest Tank Company has provided quality tanks to small and large corporations and contractors since 1972. Our reputation is built on exceptional services and customer satisfaction! Our fabrication techniques have been developed through years of tank specialization, combined with personnel who are experienced in all phases of our operation.

At Vector Systems, Inc., we are proud to specialize in the design, fabrication, and maintenance of pressure vessels, catering to the diverse needs of our valued clients. With our extensive expertise, unwavering commitment to quality, and dedication to customer satisfaction, we have established ourselves as a trusted leader in the industry. Our primary focus is on providing top-quality pressure...

More Pressure Tank Manufacturers

Types of Pressure Tanks

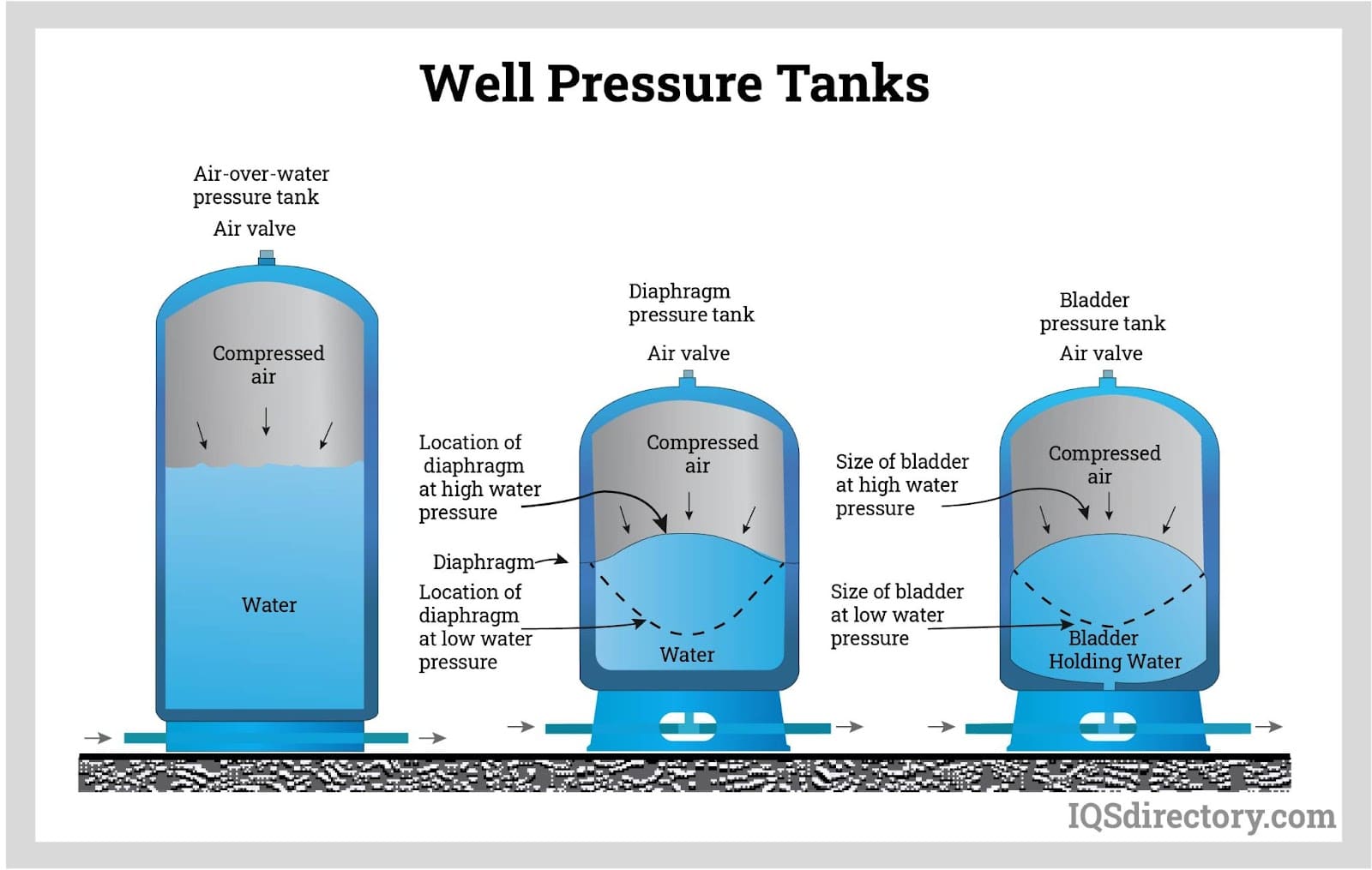

Well Pressure Tank

In a well pressure tank, there is water at the bottom and compressed air at the top. When one opens a faucet, compressed air applies pressure to the water, causing it to flow out of the tank through pipes. The pump's activity causes water from the well to fill the tank's bottom. The air at the tank's top becomes more compressed as the water level increases. The pump turns off at a maximum pressure of about 50 - 60 psi.

Bladder Pressure Tank

A bladder pressure tank features two chambers, one for compressed air and one for water. The bladder component is like a self-contained, expandable balloon filled with water. The tank sensor activates the pump. Since bladder pressure tanks don't have a diaphragm that could malfunction, they normally last longer than diaphragm pressure tanks.

Diaphragm Pressure Tank

A diaphragm pressure tank has a pressurized air chamber and a water chamber. A rubber diaphragm separates the two chambers. The diaphragm is built to increase the water level and cause the pump to turn off. Despite the effectiveness of diaphragm pressure tanks, they can fail if the diaphragm separates from the tank's sides and causes a sharp drop in water pressure. The diaphragm of a tank may also fold over on itself, which could lead to the pump running nonstop and wearing out.

Air-Over Water Pressure Tank

In an air-over-water pressure tank, the water and air charge are stored in a single, galvanized pressure tank. They often have an inner coating to prevent corrosion. The tank is glass-lined or epoxy-coated to keep the tank from rusting. In a single tank, air and water are not separated. Although air-over-water tanks are larger, they have the capacity of a smaller tank. Therefore the pump operates frequently and wears out prematurely.

Advantages of Pressure Tanks

- Pressure tanks are used in nuclear and mining industries. They securely store liquid gases and flammable chemicals.

- Pressure tanks are used for distillation and water heating.

- Using pressure tanks in water distribution systems can increase pump lifespan by softening hydraulic shocks. This is because the air inside the vessel is compressed when pumped water enters.

Applications of Pressure Tanks

- The chemical industry may use pressure tanks to create chemical reactions. In the chemical industry, numerous pressure vessel types may be used simultaneously.

- The energy industry uses pressure tanks to limit harmful gasses. Only some facilities use a reactor pressure tank. Reactor Pressure Vessels are special pressure vessels used in nuclear power plants (RPVs).

Choosing the Right Pressure Tank Company

To make sure you have the most productive outcome when purchasing pressure tanks from a pressure tank company, it is important to compare at least 5 companies using our pressure tank directory. Each pressure tank company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each pressure tank company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple pressure tank companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services