An expansion tank is required in all boiler systems for closed-loop heating. The volume of the system’s water will increase as a boiler heats it. An expansion tank uses air (or an inert gas like nitrogen) that acts as a cushion or spring against this force, as water cannot be squeezed while air can. The pressure system must stay below the boiler relief valve setting to prevent the relief valve from opening. Read More…

If you are looking for innovative pressure vessels, you’ve come to the right place! We actively manage your project every step of the way. We keep you informed of what we are doing to ensure we keep up to your standards and delivery times.

Gladwin Tank Manufacturing builds custom ASME pressure vessels. We work with stainless, carbon, duplex and the nickel alloys and offer custom rolling, plasma, and water jet cutting. Paired with our expertise in multiple welding procedures, we’re capable of handling every project, large and small. Contact us for your custom build requirements. We are more than just pressure vessels, we...

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

Midwest Tank Company has provided quality tanks to small and large corporations and contractors since 1972. Our reputation is built on exceptional services and customer satisfaction! Our fabrication techniques have been developed through years of tank specialization, combined with personnel who are experienced in all phases of our operation.

At Vector Systems, Inc., we are proud to specialize in the design, fabrication, and maintenance of pressure vessels, catering to the diverse needs of our valued clients. With our extensive expertise, unwavering commitment to quality, and dedication to customer satisfaction, we have established ourselves as a trusted leader in the industry. Our primary focus is on providing top-quality pressure...

More Expansion Tank Manufacturers

An expansion tank's primary purpose is to do that. Expansion tanks assist in giving the water a cushion to expand into when it is heated. The pressure in the boiler system may increase beyond what the system can handle if this air cushion is not present. The pressure relief valve opens as a result, allowing water to flow out.

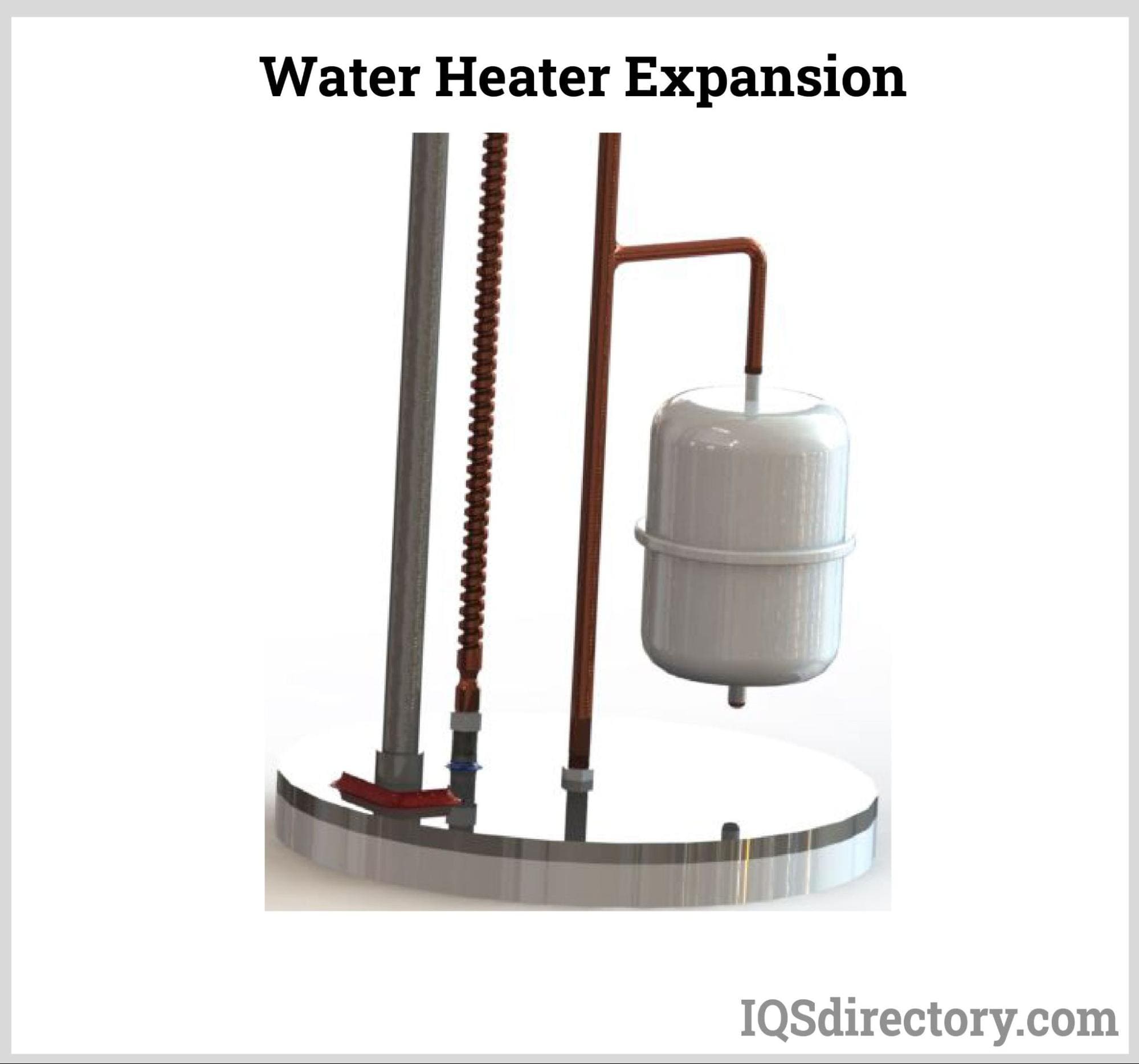

The extra pressure inside the water heater tank must be released because water expands when heated. Previously, the tank's expanding water would drain back into the municipal water supply from which it originated. Today, a check valve is used in the water main to avoid the backflow of pressure, also known as backflow.

The check valve prevents sewage from entering the water system and contaminating the freshwater supply. If a person has a "closed-loop system" brought on by any check valve or pressure regulating valve put on their home's water supply line, an expansion tank is always strongly advised. High water pressure in your home is often compared to having high blood pressure.

Expansion Tank Types

Expansion Compression Tanks

Heating and cooling systems use compression tanks to regulate pressure and absorb expansion forces. For this tank style to function properly, the air must be regulated and kept in the tank, not in the system. A compression tank, also known as a simple steel tank, is always mounted horizontally above the boiler. A gauge glass on the side of a compression tank with no internal components frequently displays the amount of air inside the tank.

The compression tank has been in use for a long time and performs excellently in particular systems. The system becomes an air control system when a simple steel expansion tank is used. Controlling the air volume, or "air cushion," in the tank above the water level is necessary. This air cushion and the water in the tank have the same surface, which enables the water to absorb the air. If the air is not put back into the cushion correctly after the water is taken out, the compression tank will fill up. After removing the water tanks, the compression tank will, likewise, become saturated if the air is not correctly reintroduced into the cushion.

Bladder Tanks

A bladder tank is an expansion tank that includes a bladder. A bladder expansion tank absorbs the expansion force and is a device used for heating and cooling. By removing or accepting the water's volume changes when it expands or contracts as a result of heating and cooling, compressed air is used to adapt to pressure fluctuations. An expansion tank that has already been air-charged is known as a pre-charged bladder tank. The advantage of bladder expansion tanks is that they allow for bladder replacement.

The bladder separates air from the expanding water. This separation avoids water contact with the tank and guards against rusting and oxygen-induced corrosion. Lowering the number of pump cycles also lengthens the pump's lifespan. In addition, this technology avoids water clogging by establishing an air barrier between the tank’s inside and the bladder’s exterior.

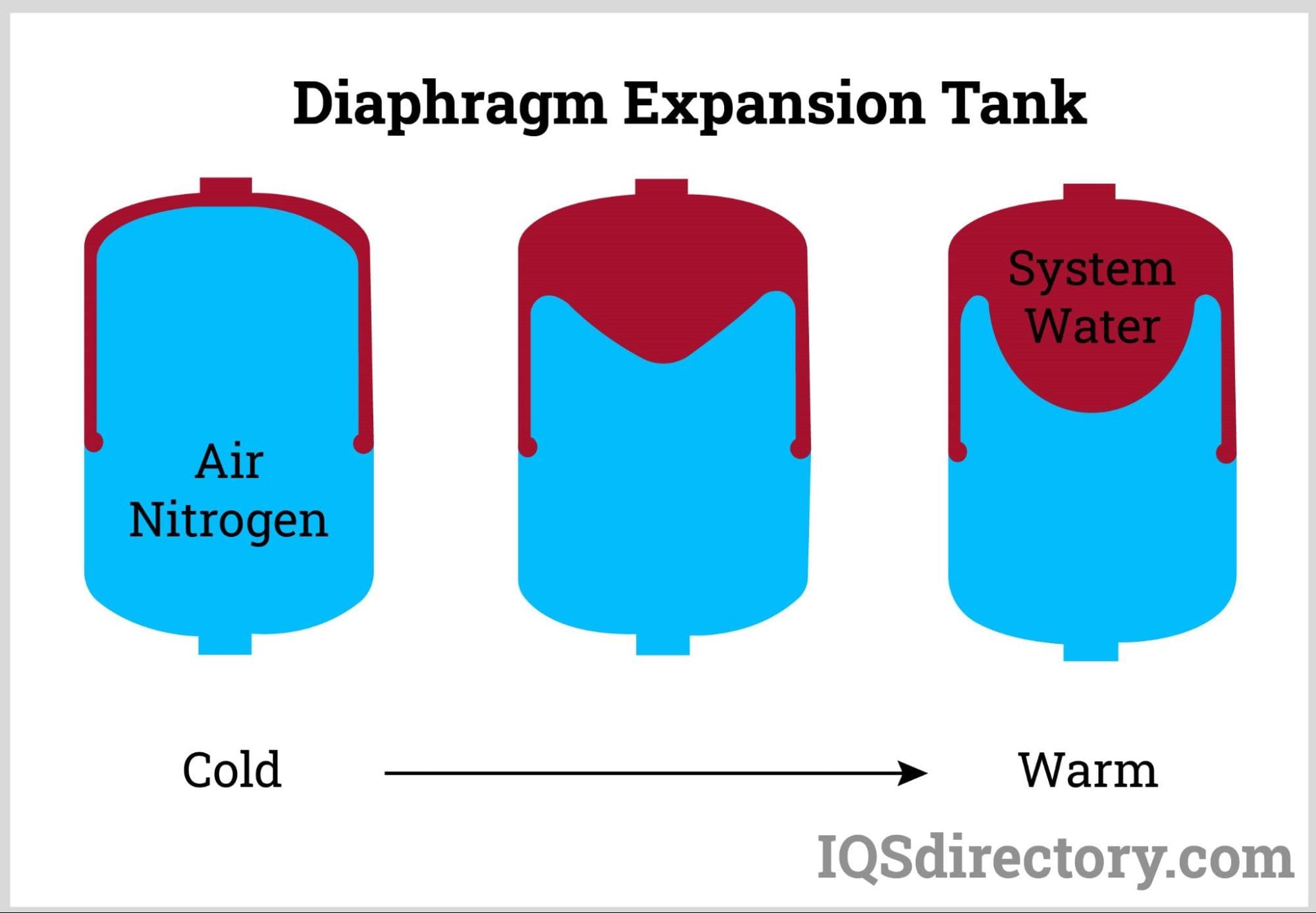

Diaphragm Tanks

Water containers called diaphragm tanks are under a lot of pressure. Manufacturers make the diaphragm tanks to keep the air and water separate inside the vessel. The operation of diaphragm tanks is comparable to that of bladder tanks. The primary difference between the two systems is the use of diaphragms versus bladders. In a tank, diaphragms cannot be changed. A vinyl tank is housed inside a bladder tank. When necessary, a bladder tank can be changed.

The diaphragm avoids air absorption and waterlogging of the system. In this way, it protects cooling and heating systems. Both the bladder and the diaphragm serve the same purpose.

Applications of Expansion Tanks

- Automotive Industry Applications: Most internal combustion engines also use an expansion tank, often known as an "overflow bottle," in their cooling system to allow the antifreeze, the coolant, and the air inside to expand with temperature. The tank is also called a "coolant recovery tank" because it draws coolant back into the cooling system when the engine cools down. This ability keeps the coolant from escaping and being lost forever.

- Large Pumping Systems: In large-scale pumping stations, similar devices, also known as an expansion chamber or a hydrophore, are used to maintain uniform pressure and reduce the effects of water hammer.

- Household Use: An expansion tank is usually a part of a home’s hydronic heating and cooling system. Its job is to keep the pressure steady when the water that moves heat expands and contracts.

Choosing the Proper Expansion Tank Manufacturer

To make sure you have the most positive outcome when purchasing expansion tanks from an expansion tank manufacturer, it is important to compare at least 4 to 5 manufacturers using our expansion tank directory. Each expansion tank manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each expansion tank company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple expansion tank companies with the same message.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services