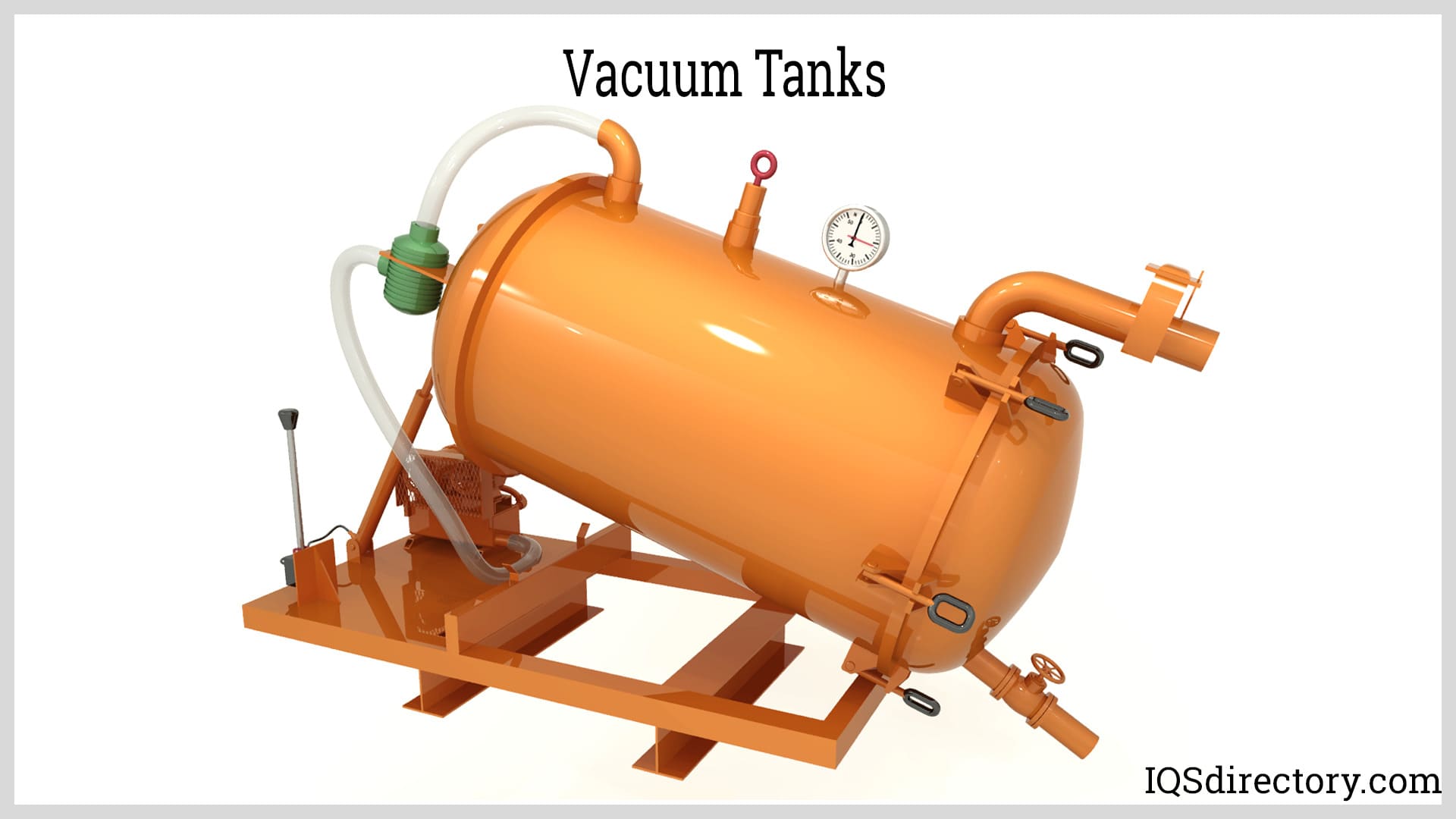

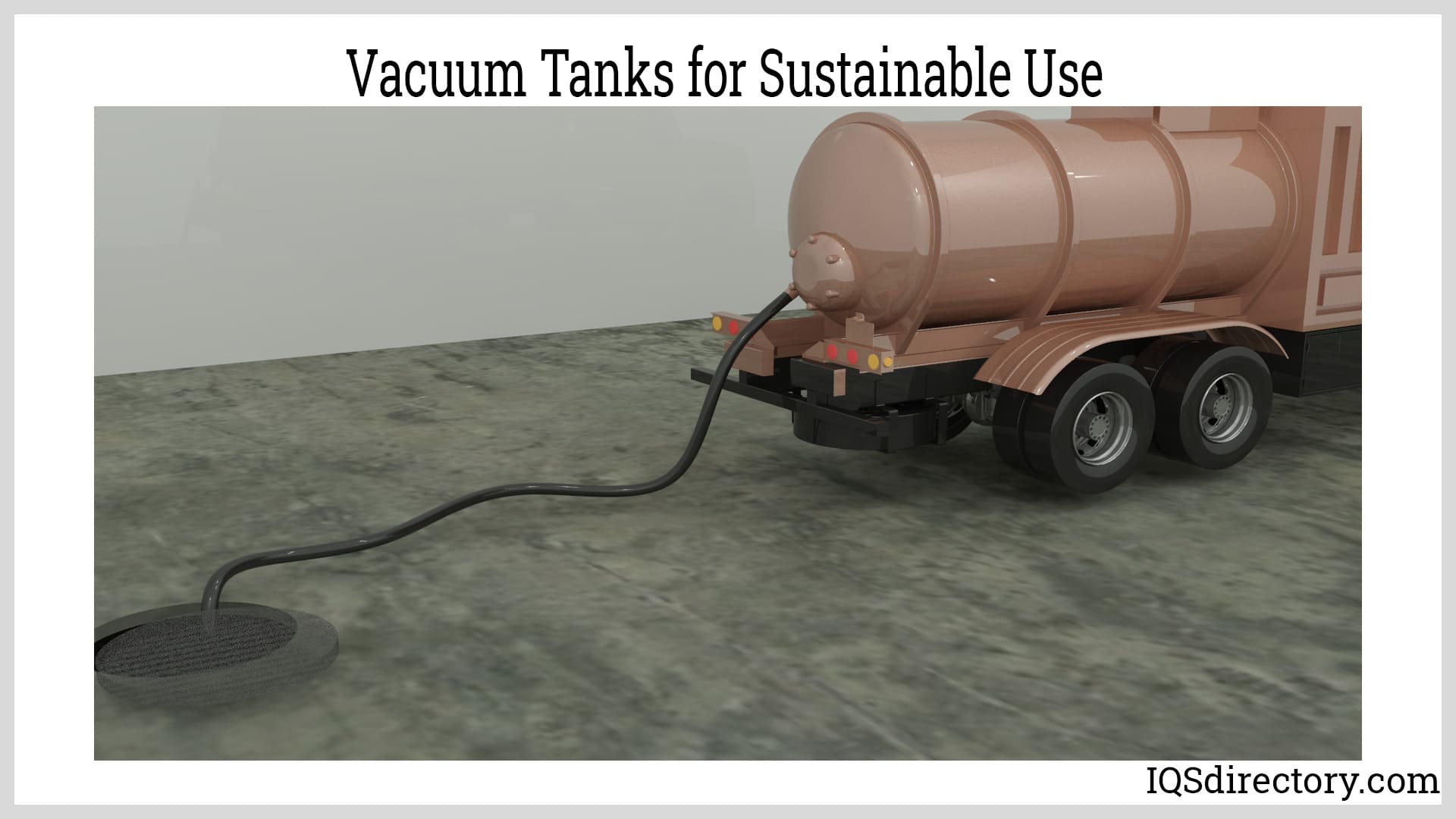

Vacuum tanks are pressure containers used to store liquid or serve as reservoirs for systems that must move enormous amounts of liquid in enclosed and safe spaces. A vacuum tank is a system component that filters air or liquids using suction, outgassing, pumping, or a combination of methods. Vacuum tanks use pressure to clean, dehydrate, and even generate power. Read More…

If you are looking for innovative pressure vessels, you’ve come to the right place! We actively manage your project every step of the way. We keep you informed of what we are doing to ensure we keep up to your standards and delivery times.

Gladwin Tank Manufacturing builds custom ASME pressure vessels. We work with stainless, carbon, duplex and the nickel alloys and offer custom rolling, plasma, and water jet cutting. Paired with our expertise in multiple welding procedures, we’re capable of handling every project, large and small. Contact us for your custom build requirements. We are more than just pressure vessels, we...

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

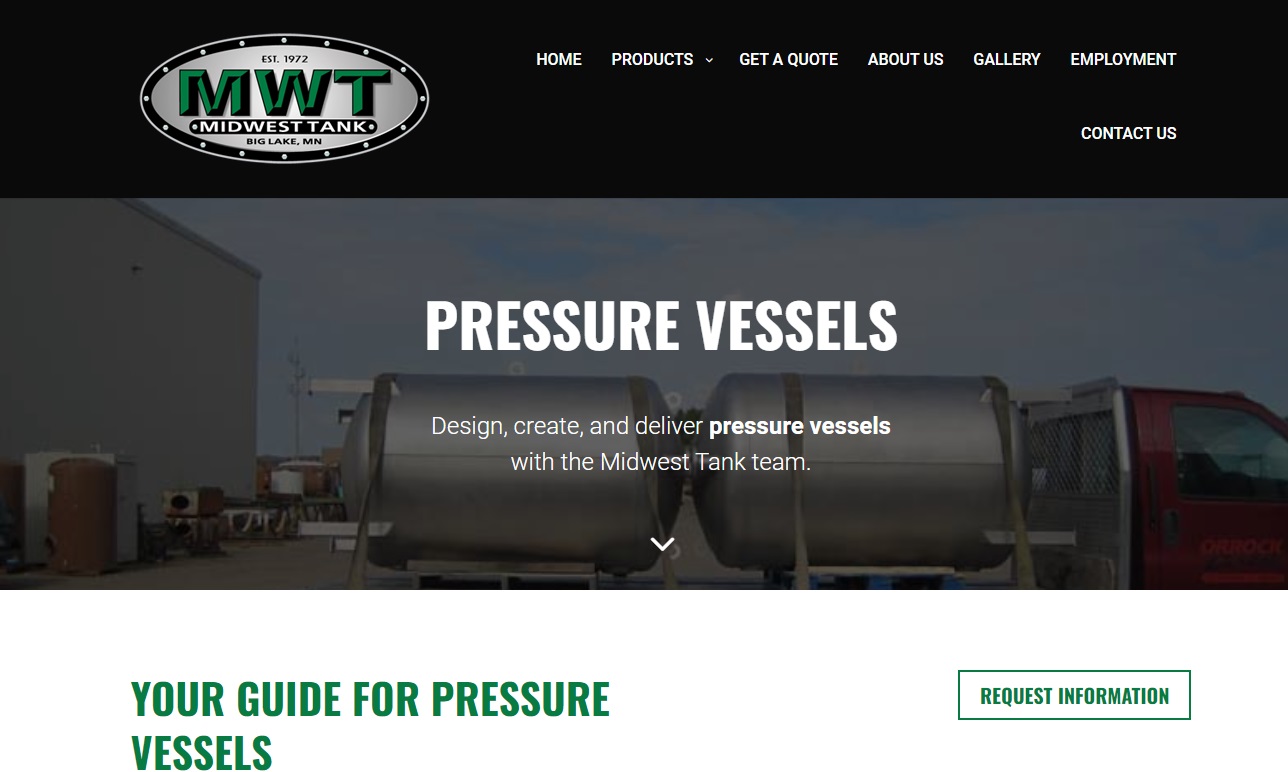

Midwest Tank Company has provided quality tanks to small and large corporations and contractors since 1972. Our reputation is built on exceptional services and customer satisfaction! Our fabrication techniques have been developed through years of tank specialization, combined with personnel who are experienced in all phases of our operation.

At Vector Systems, Inc., we are proud to specialize in the design, fabrication, and maintenance of pressure vessels, catering to the diverse needs of our valued clients. With our extensive expertise, unwavering commitment to quality, and dedication to customer satisfaction, we have established ourselves as a trusted leader in the industry. Our primary focus is on providing top-quality pressure...

More Vacuum Tank Manufacturers

However, not all vessels can survive the pressure differential caused by a vacuum between the inside and outside of the vessel. Manufacturers must, therefore, carefully evaluate whether a vacuum tank will be required when developing a system that will use fluctuations in internal and external pressure to ensure the system's success and the operator's safety.

The Operation of Vacuum Tanks

Vacuum tanks are ideal for excavation since they use high-pressure hoses, which prevent any damage. Negative air pressure is produced by a pump, providing the vacuum with incredibly strong suction. The vacuum produces a stronger suction the more powerful the pump is.

Pumps that produce the necessary pressure to create a vacuum are always in vacuum tanks. There are many various sizes and strengths of vacuum pumps. Some, for instance, are so big that they need a separate power source, while others are little enough to be powered by the battery of the car in which they're housed.

In any case, vacuum tanks and pumps serve three primary types of vacuum systems. The three common systems are the direct vacuum system, the eductor vacuum system, and the centrifugal vacuum system. Eductor vacuums transfer pressured water through an eductor, which forms a vacuum using a centrifugal pump. Direct vacuums draw liquid or air into the tank through the vacuum pump. Direct vacuum systems use wide profile, heavy wall tubing to perform their task.

Last but not least, closed-loop centrifugal blower vacuum systems are made for precise tolerances. As one might expect, centrifugal blower vacuum systems utilize a blower. In this instance, the blower operates in reserve and induces a vacuum inside the reservoir. In the meantime, a tubing system joins them to transfer liquids and gases from the reservoir to the higher tank.

Applications of Vacuum Tanks

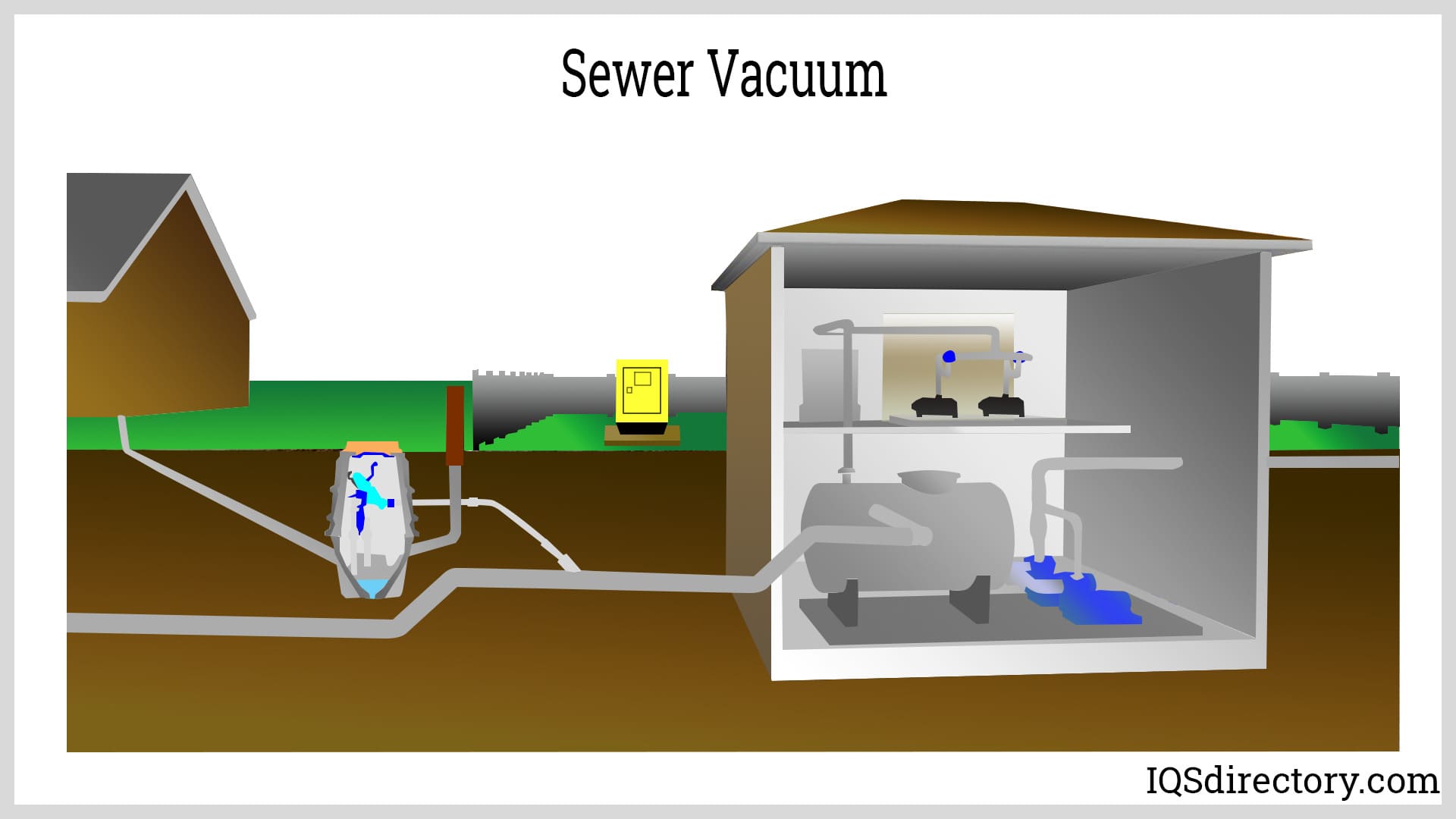

Vacuum Tanks for Sewer Cleaning

Vacuum tanks are frequently used to clean septic tanks and sewers. The system's functionality is improved, backups are decreased, and flooding is decreased thanks to the sewage vacuum tank's ability to remove sludge and buildup. They are also used to empty portable bathrooms on construction sites and in the aviation industry. The material is then appropriately disposed of into the sewer system. Additionally, the design of vacuum tanks enables the evacuation and storage of potentially harmful waste.

Industrial Use of Vacuum Tanks

A jet vac tanker is used during certain drilling operations or hydro excavation projects to remove debris, sludge, and water from a site, making the area safer and cleaner. In addition, to reveal utility lines that require replacement or repair, they are also used to suck away liquids and dirt.

Vacuum Tanks and Emergency Services

Yes, the basic vacuum tank is employed in both disaster relief and dealing with environmental issues. For example, vacuum trucks can clean up oil, hazardous waste spills, and other dangerous items. Additionally, they have been used to safely rescue persons trapped in mines and trenches by sucking hazardous water and mud from the scene. Vacuum tanks can pump extra water from your property if your house or basement floods, minimizing long-term damage.

Vacuum Tanks and the Environment

Large-scale vacuum tankers can be called in to safeguard important places and wildlife in the case of a flood or storm. Before these areas are irreversibly harmed, vacuum tanks eliminate extraneous liquids from the area. They can also be used in infrastructure development.

Considerations When Buying a Vacuum Tank

Vacuum tanks can be custom finished by various manufacturers utilizing various secondary processing techniques, just like other high-pressure vessels. Tanks linked to vehicles for substance-clearance applications may benefit significantly from strengthening and resistance-building changes. Vacuum tanks can also vary substantially depending on their size and intended use. Owners of vacuum tanks must be careful to fully clean the vessel after storing and processing to keep the tank healthy and functional. Owners should also be aware that they must never use vacuum tanks or any other pressure vessels that are rusted or otherwise damaged in order to prevent injury or property damage. A damaged tank could explode or spew shrapnel due to the pressure built inside it. Contact knowledgeable companies for more safety advice and information on maintaining a vacuum tank.

Choosing the Right Vacuum Tank Supplier

To make sure you have the most productive outcome when purchasing vacuum tanks from a vacuum tank supplier, it is important to compare at least 4 to 5 companies using our list of vacuum tank suppliers. Each vacuum tank supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each vacuum tank company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple vacuum tank companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services